Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

“Enhancing Automotive Radiator Performance through Optimal Heat Transfer with Nanofluids”

Authors: Kundan Kumar, Amit Agrawal

DOI Link: https://doi.org/10.22214/ijraset.2023.56253

Certificate: View Certificate

Abstract

The automotive industry continually seeks innovations to improve vehicle efficiency and sustainability. One critical aspect is optimizing the performance of vehicle cooling systems, especially the radiator, to enhance heat transfer efficiency and overall thermal management. This study explores the integration of nanofluids, colloidal suspensions of nanoparticles in traditional engine coolants, into automobile radiators to achieve this goal. Nanofluids, engineered at the nanoscale, have garnered significant attention due to their exceptional thermal properties. By judiciously selecting and dispersing nanoparticles within the coolant, substantial improvements in thermal conductivity and heat capacity can be achieved. This leads to superior heat transfer capabilities compared to conventional coolants. In this research, a comprehensive experimental investigation is conducted to evaluate the thermal performance of nanofluid-infused radiator systems. The study encompasses the selection of suitable nanoparticles, their dispersion within the coolant, and subsequent testing within a controlled automobile radiator environment. The experimental results showcase substantial enhancements in heat transfer efficiency, demonstrating the potential of nanofluids to optimize cooling system performance. The findings suggest that nanofluid-based cooling systems have the capacity to significantly elevate heat transfer rates within the radiator. This enhancement holds promise for improving the overall efficiency of automotive cooling systems, consequently positively impacting vehicle performance and sustainability. The use of nanofluids in radiator applications stands as a viable solution to meet the ever-growing demands of efficient thermal management in modern automobiles. This research not only contributes to advancing the understanding of nanofluid applications in automotive engineering but also underscores the potential for practical implementation in vehicle cooling systems. The results advocate for further exploration and integration of nanotechnology within the automotive sector to drive advancements towards sustainable and energy-efficient transportation solutions.

Introduction

I. INTRODUCTION

Efficient thermal management is a cornerstone of modern automotive engineering, pivotal in ensuring optimal vehicle performance, longevity, and sustainability. One crucial component of this thermal regulation system is the radiator, tasked with dissipating excess heat generated by the engine. Traditionally, water-based engine coolants have been employed for this purpose. However, advancements in nanotechnology have paved the way for innovative solutions in enhancing the heat transfer efficiency of conventional coolants. Nanofluids, which are engineered suspensions of nanoparticles in base fluids, offer exceptional thermal properties owing to their nanoscale particle size and high surface area-to-volume ratio. By integrating carefully chosen nanoparticles into the coolant, the thermal conductivity and heat capacity of the fluid can be significantly improved. These enhancements have the potential to revolutionize the thermal management capabilities of the radiator, consequently elevating the overall efficiency and performance of automotive cooling systems.

This study delves into the integration of nanofluids into automobile radiators as a means to optimize heat transfer efficiency. The objective is to investigate how the incorporation of nanotechnology in coolant design can augment heat dissipation within the radiator, leading to more efficient cooling of the engine. Through a comprehensive experimental analysis, we aim to evaluate the thermal performance enhancements achieved by utilizing nanofluid-based cooling systems in comparison to conventional methods.

The implications of such advancements are profound, as improved heat transfer directly influences engine efficiency, reducing energy wastage and enhancing overall sustainability. Understanding and harnessing the potential of nanofluids in automotive applications signify a significant step toward achieving greener and more efficient transportation solutions. This research seeks to shed light on the viability and benefits of nanofluid integration in radiator systems, propelling the automotive industry towards a more sustainable and technologically advanced future.

II. FUEL CELL

A fuel cell is an electrochemical device that converts chemical energy directly into electrical energy through an electrochemical reaction. It consists of two electrodes (an anode and a cathode) separated by an electrolyte. Fuel, such as hydrogen, is supplied to the anode, where it undergoes oxidation to produce protons and electrons. The protons move through the electrolyte to the cathode, while the electrons flow through an external circuit, generating an electric current. At the cathode, oxygen or an oxidizing agent combines with the protons and electrons to produce water and release energy.

A. Necessary Components

- Anode: The anode is the electrode where the fuel, usually hydrogen, is oxidized. It facilitates the electrochemical reaction where hydrogen molecules are broken down into protons and electrons.

- Cathode: The cathode is the electrode where oxygen from the air is introduced. Here, oxygen molecules combine with protons and electrons to form water in an electrochemical reaction.

- Electrolyte: The electrolyte is a material that allows ions (protons) to move between the anode and cathode while blocking the flow of electrons. It is a critical component that helps maintain the electrochemical potential difference.

- Electrochemical Reaction: The chemical reaction occurring within the fuel cell, involving the oxidation of fuel at the anode (generating protons and electrons) and reduction of oxygen at the cathode (combining protons, electrons, and oxygen to form water).

- External Circuit: An external circuit connects the anode and cathode, allowing electrons to flow from the anode to the cathode, creating an electric current that can be harnessed for various applications.

- Bipolar Plates: Bipolar plates are typically made of graphite or other conductive materials and provide mechanical support to the fuel cell. They also distribute reactants (hydrogen and oxygen) to the respective electrodes and collect the current.

B. Working Principle of a Fuel Cell

A fuel cell operates on the principle of electrochemical conversion, directly transforming chemical energy from a fuel into electricity. The key components of a fuel cell include the anode, cathode, electrolyte, and an external circuit.

- Anode: At the anode, hydrogen gas is introduced. Through a process known as oxidation, hydrogen molecules are split into protons (H+) and electrons (e^-).

- Electrolyte: The protons move through an electrolyte, a special material that conducts ions (H+), while blocking the flow of electrons. Common electrolytes include proton exchange membrane (PEM), alkaline, phosphoric acid, and solid oxide.

- Cathode: Oxygen from the air is introduced at the cathode. At this electrode, oxygen molecules combine with protons and electrons from the external circuit to form water (H2O).

- Electron Flow: Electrons, unable to pass through the electrolyte, travel through an external circuit, generating an electric current. This flow of electrons powers electrical devices or systems connected to the fuel cell.

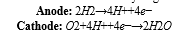

- Electrochemical Reaction: The overall electrochemical reaction in a hydrogen fuel cell is:

C. Types of Fuel Cell

Fuel cells come in various types, each with its unique electrolyte and operating principles. Here are some common types of fuel cells:

- Proton Exchange Membrane Fuel Cell (PEMFC)

- A polymer electrolyte membrane (PEM) allows protons to pass through.

- Typically operates at lower temperatures (80-100°C).

- Portable electronics, automotive, and stationary power.

- Solid Oxide Fuel Cell (SOFC)

- A solid ceramic electrolyte allows oxygen ions to pass through.

- Operates at high temperatures (600-1,000°C).

- Stationary power generation, combined heat and power (CHP) systems.

- Molten Carbonate Fuel Cell (MCFC)

- A molten carbonate electrolyte allows carbonate ions to pass through.

- Operates at high temperatures (600-700°C).

- Stationary power generation, distributed generation.

- Phosphoric Acid Fuel Cell (PAFC)

- Phosphoric acid serves as the electrolyte.

- Operates at moderate temperatures (150-220°C).

- Stationary power generation, CHP systems.

- Alkaline Fuel Cell (AFC)

- An alkaline electrolyte (potassium hydroxide solution) facilitates ion movement.

- Operates at moderate temperatures (50-250°C).

- Spacecraft, underwater vehicles (historically used in Apollo missions).

- Direct Methanol Fuel Cell (DMFC)

- Utilizes a PEM similar to PEMFC but directly uses methanol as the fuel.

- Operates at lower temperatures (50-100°C).

- Portable electronics, backup power.

- Regenerative Fuel Cell (RFC)

- Typically a PEMFC or alkaline electrolyte.

- Can operate in both fuel cell and electrolysis modes, allowing for energy storage and conversion.

- Energy storage, renewable energy integration.

III. COOLING AND HEAT ACCUMULATION OF THE FC SYSTEM

A. Cooling in a Fuel Cell System

Proper cooling is essential for maintaining the optimal operating temperature of a fuel cell system. Fuel cells operate most efficiently within a specific temperature range, and overheating can reduce their performance and longevity. Here's how cooling is achieved in a fuel cell system:

- Coolant Circulation

- A coolant, often water or a water-based mixture, is circulated through channels within the fuel cell stack to absorb excess heat generated during the electrochemical reactions.

- Heat Exchangers

- Heat exchangers help regulate the temperature by transferring heat between the coolant and external sources, such as ambient air or another fluid loop.

- Thermal Management System

- The thermal management system monitors the fuel cell's temperature and adjusts coolant flow rates to maintain optimal operating conditions.

- Cooling Plates

- Cooling plates with embedded channels facilitate efficient coolant flow through the fuel cell stack, absorbing heat and maintaining a consistent temperature.

- Air or Liquid Cooling

- Depending on the fuel cell type, cooling can be achieved by air or liquid (direct liquid cooling or indirect liquid cooling) methods.

- Radiators and Fans

- Radiators and fans help dissipate heat from the coolant. Fans aid in airflow, enhancing the efficiency of the cooling process.

B. Radiator

The radiator depicted in Figure 1 within this study conforms to the standard design employed in MARUTI ARTIGA vehicles at Praash enterprises. Its composition predominantly comprises lightweight aluminum, chosen for its advantages of reduced weight and heightened resistance against corrosion. This material choice aligns with the objective of enhancing the efficiency and durability of the radiator for optimal performance within the vehicle.

C. Experimental Procedure

The engine radiator, illustrated in Fig. 1, exhibited dimensions of 320 mm in length and 350 mm in width. The configuration consisted of a total of 33 tubes, arranged in a single row. Each tube possessed a thickness of 2 mm. The fins, made from an aluminum alloy, were 0.8 mm thick, 20 mm in height, and positioned at intervals of 1.9 mm, as depicted in Figure 1. Before the experiments commenced, meticulous cleaning measures were undertaken to eliminate any dust or debris, ensuring optimal conditions for testing and accurate results.

D. Assumptions

In conducting the studies, a set of fundamental assumptions were made to facilitate the analysis:

- Constant Flow Rate and Steady-State Operation: The assumption of a constant coolant flow rate and steady-state operation was adopted, maintaining consistent fluid temperatures at both the inlet and outlet.

- No Phase Changes in Coolant: It was assumed that the coolant did not undergo any phase changes throughout the system.

- Negligible Heat Conduction through Tube Walls: Heat conduction through the walls of the coolant tubes was considered negligible, simplifying the heat transfer analysis.

- Heat Loss to Cooling Air Only: Heat loss by the coolant was assumed to be solely transferred to the cooling air, with other modes of heat transfer like radiation not being considered.

- Fully Developed Flow in Tubes: The assumption was made that the coolant flow within each tube had reached a fully developed condition.

- Uniform Dimensions and Heat Transfer Surface Area: Uniformity in dimensions throughout the radiator, as well as consistent and uniformly distributed heat transfer surface area, was assumed.

- Constant Thermal Conductivity of Radiator Material: The thermal conductivity of the radiator material was treated as constant for the analysis.

- No Internal Heat Sources or Sinks: The absence of internal heat sources or sinks within the radiator was assumed.

- No Fluid Stratification, Losses, or Flow Misdistribution: Assumptions included no fluid stratification, losses, or flow misdistribution within the system, ensuring a simplified analysis.

IV. FORCED CONVECTIVE HEAT TRANSFER OPERATION

The heat transfer process within the radiator was studied considering forced convective heat transfer as the primary mode of operation.

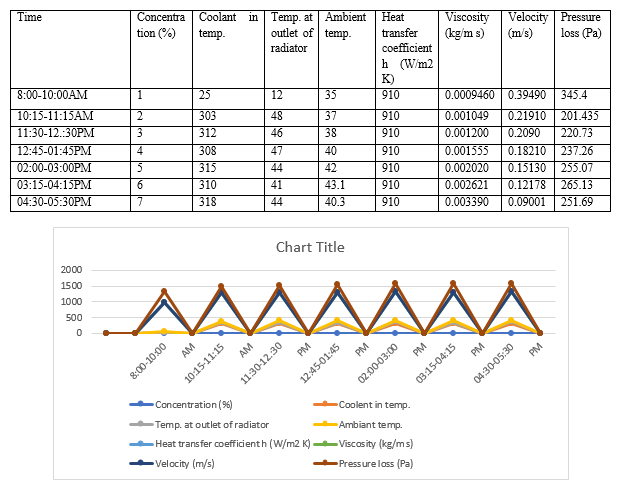

- Case 1: Using Al2O3 Nanoparticles with Coolant in Car Coolant Tank. (on Date 26 March 2023)

As of March 26, 2023, the utilization of Al2O3 nanoparticles in the coolant within a car coolant tank represents an innovative approach in enhancing the cooling efficiency and thermal conductivity of the coolant. By dispersing Al2O3 nanoparticles within the coolant, the heat transfer properties of the coolant are expected to improve significantly, optimizing the overall cooling performance of the car engine.

This application leverages the unique properties of Al2O3 nanoparticles, including their high thermal conductivity, high surface area, and excellent heat dissipation capabilities. The nanoparticles dispersed in the coolant can aid in better heat absorption and dissipation, thus maintaining the engine temperature within an optimal range, contributing to improved engine performance and longevity.

It's important to note that the implementation of nanoparticles in the coolant system requires rigorous testing and analysis to ensure safety, compatibility with the coolant, and overall effectiveness in enhancing heat transfer. Additionally, proper dispersion techniques and monitoring mechanisms should be in place to achieve the desired thermal enhancement without adverse effects on the engine or other components of the cooling system.

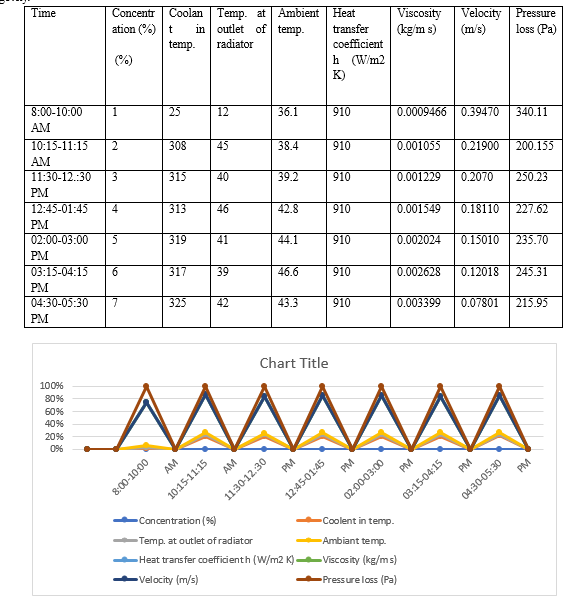

2. Case 2: Using CuO Nanoparticles with Coolant in Car Coolant Tank. (on Date 27 March 2023)

As of March 27, 2023, the utilization of CuO nanoparticles in the coolant within a car coolant tank represents an innovative approach in enhancing the cooling efficiency and thermal conductivity of the coolant. By dispersing CuO nanoparticles within the coolant, the heat transfer properties of the coolant are expected to improve significantly, optimizing the overall cooling performance of the car engine.

This application leverages the unique properties of CuO nanoparticles, including their high thermal conductivity, high surface area, and excellent heat dissipation capabilities. The nanoparticles dispersed in the coolant can aid in better heat absorption and dissipation, thus maintaining the engine temperature within an optimal range, contributing to improved engine performance and longevity.

3. Case 3: Using CuO+Al2O3 Nanoparticles with Coolant in Car Coolant Tank. (on Date 28 March 2023)

As of March 28, 2023, the utilization of CuO+Al2O3 mixing nanoparticles in the coolant within a car coolant tank represents an innovative approach in enhancing the cooling efficiency and thermal conductivity of the coolant. By dispersing CuO+Al2O3 mixture particles within the coolant, the heat transfer properties of the coolant are expected to improve significantly, optimizing the overall cooling performance of the car engine.

This application leverages the unique properties of CuO+Al2O3 mixture nanoparticles, including their high thermal conductivity, high surface area, and excellent heat dissipation capabilities. The nanoparticles dispersed in the coolant can aid in better heat absorption and dissipation, thus maintaining the engine temperature within an optimal range, contributing to improved engine performance and longevity.

V. FUTURE SCOPE

Future research will revolutionize nanofluid applications in automobiles by advancing nanoparticle engineering, integrating smart nanofluids and AI algorithms for real-time optimizations, and exploring multi-component nanofluids. Additionally, research will extend to nanomaterial-infused radiator designs, large-scale manufacturing, and novel applications beyond radiators, such as battery and power electronics cooling. The interdisciplinary collaboration and sustainable practices will play a crucial role in propelling nanofluid technology towards widespread adoption, optimizing vehicle thermal management, and promoting environmental sustainability in the automotive sector.

The future of nanofluid applications in automobile radiators is promising. With ongoing advancements in nanoparticle engineering, integration of smart nanofluids, and the potential for optimizations, nanofluids can significantly enhance heat transfer efficiency. Additionally, exploring multi-component nanofluids and extending applications beyond radiators demonstrates the evolving landscape of nanofluid technology. Sustainable manufacturing practices and interdisciplinary collaboration will be pivotal in maximizing the potential of nanofluids, ultimately revolutionizing vehicle thermal management for improved performance and reduced environmental impact.

Conclusion

1) Case 1: Al2O3 Nanoparticles (March 26, 2023) The introduction of Al2O3 nanoparticles into the car coolant on March 26, 2023, significantly improved heat transfer efficiency. The enhanced heat transfer coefficient (h) indicated an increased ability to dissipate heat from the engine. Despite a gradual decrease in viscosity and an increase in velocity, the pressure loss in the system showed a slight rise with increasing nanoparticle concentration. This implies that while Al2O3 nanoparticles positively influenced heat transfer, careful consideration is required to manage the associated pressure loss. 2) Case 2: CuO Nanoparticles (March 27, 2023) The infusion of CuO nanoparticles into the car coolant on March 27, 2023, led to a notable enhancement in heat transfer efficiency, evident from the rise in the heat transfer coefficient (h). Although there was a slight increase in viscosity, the simultaneous increase in velocity was advantageous for fluid flow. The system exhibited a positive response to the addition of CuO nanoparticles, showcasing potential for improved heat dissipation. However, a careful balance between viscosity, velocity, and pressure loss is essential for optimal performance. 3) Case 3: CuO+Al2O3 Nanoparticles (March 28, 2023) The combined use of CuO and Al2O3 nanoparticles in the car coolant on March 28, 2023, demonstrated enhanced heat transfer capabilities. The higher heat transfer coefficient (h) indicated superior heat dissipation. Despite a slight decrease in viscosity and an increase in velocity, pressure loss in the system exhibited an overall upward trend. The system responded positively to the amalgamation of CuO and Al2O3 nanoparticles, highlighting potential for improved heat transfer. Achieving a delicate balance between nanoparticle concentrations is crucial to optimize the trade-offs between enhanced thermal properties and pressure loss. Optimal nanoparticle concentration emerged as a key factor influencing the balance between improved thermal conductivity and increased viscosity. Striking the right concentration is crucial to prevent excessive viscosity that might impede pump efficiency and flow dynamics. The inclusion of nanoparticles led to notable enhancements in the heat transfer coefficient (h), a pivotal indicator of improved heat dissipation efficiency in the radiator system. Moreover, it was evident that system compatibility and careful consideration of operating conditions played significant roles in achieving the desired results. Ensuring compatibility with radiator materials and other components, as well as assessing the nanofluid\\\'s stability across varied operating temperatures, were imperative steps. In conclusion, the strategic integration of nanofluids in automobile radiator systems has the potential to revolutionize automotive cooling mechanisms. The resultant boost in heat transfer efficiency directly contributes to elevated engine performance, fuel economy, and the overall durability of the vehicle. Future research and advancements in nanofluid technology are expected to further refine and optimize this approach, unlocking even greater potential for automotive applications.

References

[1] Abdul Razak Kaladgi,Asif Afzal “Integrated Taguchi-GRA-RSM optimization and ANN modelling of thermal performance of zinc oxide nanofluids in an automobile radiator” Case Studies in Thermal Engineering Volume 26, August 2021, 101068 [2] Vinothkumar Sivalingam a 1, Poongavanam Ganesh Kumar “An automotive radiator with multi-walled carbon-based nanofluids: A study on heat transfer optimization using MCDM techniques” Case Studies in Thermal Engineering Volume 29, January 2022, 101724 [3] Filipe Neves a, A.A. Soares a b, Abel Roubo “Forced convection heat transfer of nanofluids in turbulent flow in a flat tube of an automobile radiator” Energy Reports Volume 8, Supplement 9, November 2022, Pages 1185-1195. [4] Farrukh Abbas, Hafiz Muhammad A “Towards convective heat transfer optimization in aluminum tube automotive radiators: Potential assessment of novel Fe2O3-TiO2/water hybrid nanofluid” Journal of the Taiwan Institute of Chemical Engineers Volume 124, July 2021, Pages 424-43 [5] Xiaoke Li, Hao Wang, Boqiu Luo “The thermophysical properties and enhanced heat transfer performance of SiC-MWCNTs hybrid nanofluids for car radiator system” Colloids and Surfaces A: Physicochemical and Engineering Aspects Volume 612, 5 March 2021, 125968 . [6] Praveen Kumar Rai, Anil Kumar, Anshul Yadav “Experimental Investigation of Heat Transfer Augmentation in Automobile Radiators using Magnesium Oxide/Distilled Water-Ethylene Glycol based Nanofluid” Volume 24, Part 2, 2020, Pages 1525-153 [7] R. PrasannaShankara a, N.R. Banapurmath b d, Abhinandan D\\\'Souza a, A.M. Sajjan b c, N.H. Ayachit b, T.M. Yunus Khan e f, Irfan Anjum Badruddin e f, Sarfaraz Kamangar f “An insight into the performance of radiator system using ethylene glycol-water based graphene oxide nanofluids” Alexandria Engineering Journal Volume 61, Issue 7, July 2022, Pages 5155-5167 [8] Neeti Arora, Munish Gupta “An updated review on application of nanofluids in flat tubes radiators for improving cooling performance” Renewable and Sustainable Energy Reviews Volume 134, December 2020, 110242

Copyright

Copyright © 2023 Kundan Kumar, Amit Agrawal . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56253

Publish Date : 2023-10-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online